CNC 3D Printer

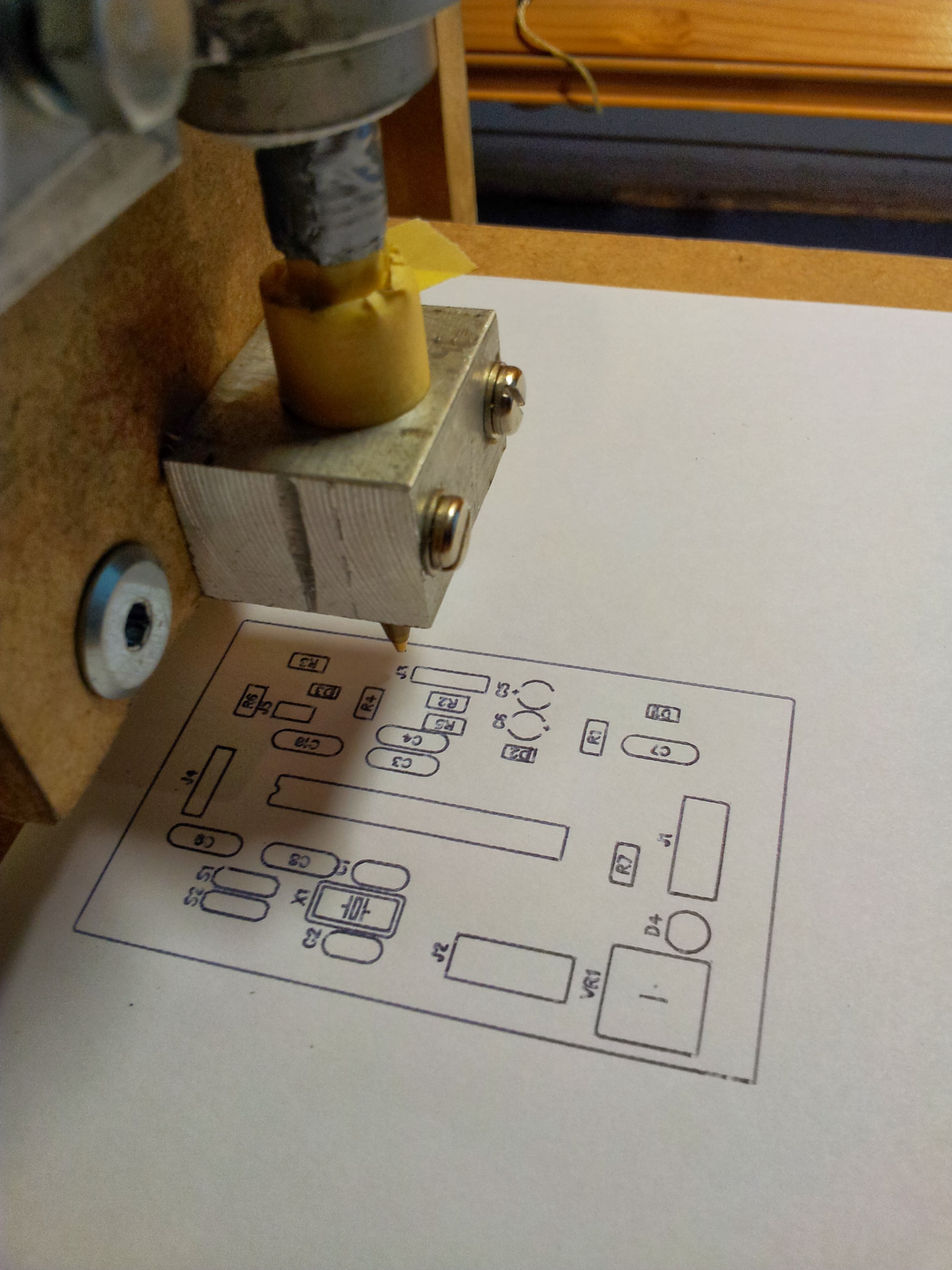

This started out as a CNC machine because I needed a quick way of drilling a lot of PCBs for a club project.It uses three NEMA 23 stepper motors driven by homemade controllers based on the A3977 chip. I use Diptrace schematic and layout software to design the PCBs and Mach3 software to read the gcode files and drill the blank pcbs.I later adapted it to take Staedtler Ultra fine tip permanent marker pens to draw the component layout on the pcbs from dxf files output by Diptrace. Then I added a hotend and filament feed to use it for 3D printing.

PCB Exposure Box

I built this to make small pcbs for use for my own electronics hobby use. It uses UV LEDs as the light source and includes a timer kit made by Vellerman.The films I use are output from Diptrace and double printed on OHP film on an HP inkjet printer. Exposure time is approx 2-3 mins.

PDRAW Layout capture

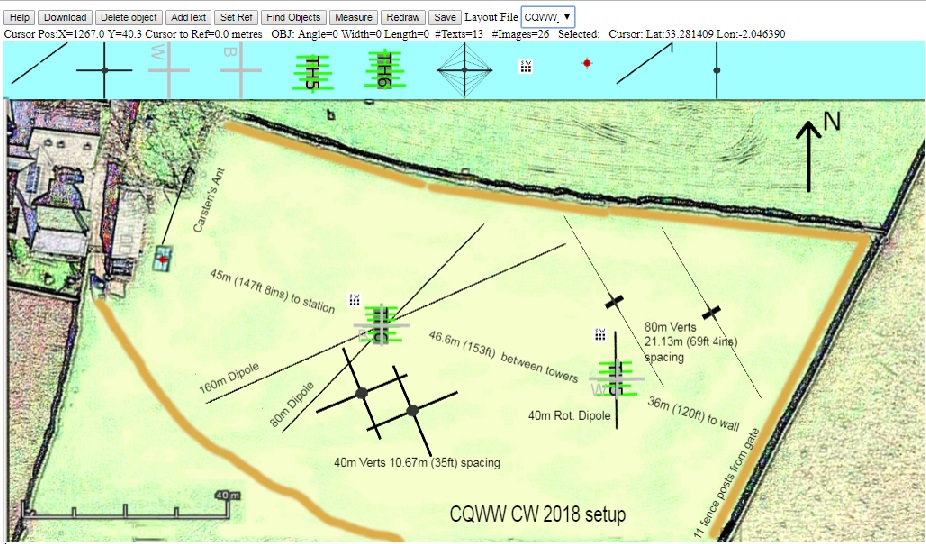

I designed this application to assist in the decision making for which antennas we plan to use for a contest. It is written in Javascript with PHP and AJAX routines on the server. We now agree the layout in a meeting and the agreed layout is held on my website for all to view and edit.

Rotator Brake

I designed and built this to add a braking system to a G600 Yaesu rotator. It uses a powerful solenoid to retract a detent pin from a hole in ring around the moveable section of the rotator. The holes are 10 degrees apart giving 36 positions at which the rotator can be locked. This is necessary to prevent strong winds from turning the antenna.